Reach Stacker Luffing Cylinder

As one of the hydraulic cylinder manufacturers, suppliers, and exporters of mechanical products, We offer hydraulic cylinders and many other products.

Please get in touch with us for details.

Hydraulic Cylinder

A reach stacker luffing cylinder is a hydraulic cylinder that is used to raise and lower the boom of a reach stacker. The boom is the telescoping arm that is used to lift and move containers. The luffing cylinder allows the boom to be tilted up and down, which is necessary for loading and unloading containers from different heights.

Reach stacker luffing cylinders are typically made of high-strength steel and are designed to withstand heavy loads. They are also equipped with a variety of features to ensure smooth and reliable operation, such as wear-resistant seals, anti-corrosion coatings, and pressure relief valves.

Reach stacker luffing cylinders are an essential component of reach stackers, and they play a vital role in the loading and unloading of containers at ports and other industrial facilities.

Features and Benefits of Reach Stacker Luffing Cylinders:

Here are some of the key features and benefits of reach stacker luffing cylinders:

1. High strength and durability: Reach stacker luffing cylinders are made of high-strength steel and are designed to withstand heavy loads. This ensures that they can operate reliably and safely even under demanding conditions.

2. Smooth and precise operation: Reach stacker luffing cylinders are equipped with a variety of features to ensure smooth and precise operation, such as wear-resistant seals and anti-corrosion coatings. This helps to reduce wear and tear on the cylinder and ensures that it can operate smoothly and efficiently for many years.

3. Wide range of temperature resistance: Reach stacker luffing cylinders are designed to operate in a wide range of temperatures, from -40°C to +100°C. This makes them ideal for use in a variety of climates.

4. Easy maintenance: Reach stacker luffing cylinders are relatively easy to maintain. The seals and other components can be replaced relatively easily, and the cylinder can be inspected and lubricated regularly to ensure that it is operating properly.

Overall, reach stacker luffing cylinders are an essential component of reach stackers and play a vital role in the loading and unloading of containers at ports and other industrial facilities. They are designed to be high-strength, durable, and easy to maintain, and they can operate reliably and safely in a wide range of temperatures.

Reach Stacker Luffing Cylinder Specifications:

| Product Name | Reach Stacker Luffing Cylinder |

| Features: | Realize the up-and-down tilting of the boom |

| Bore diameter: | 100mm~220mm |

| Rod diameter: | 60mm~140mm Stroke≤5000mm |

| Pressure: | Maximum 30MPa |

| Applications: | Reach Stacker |

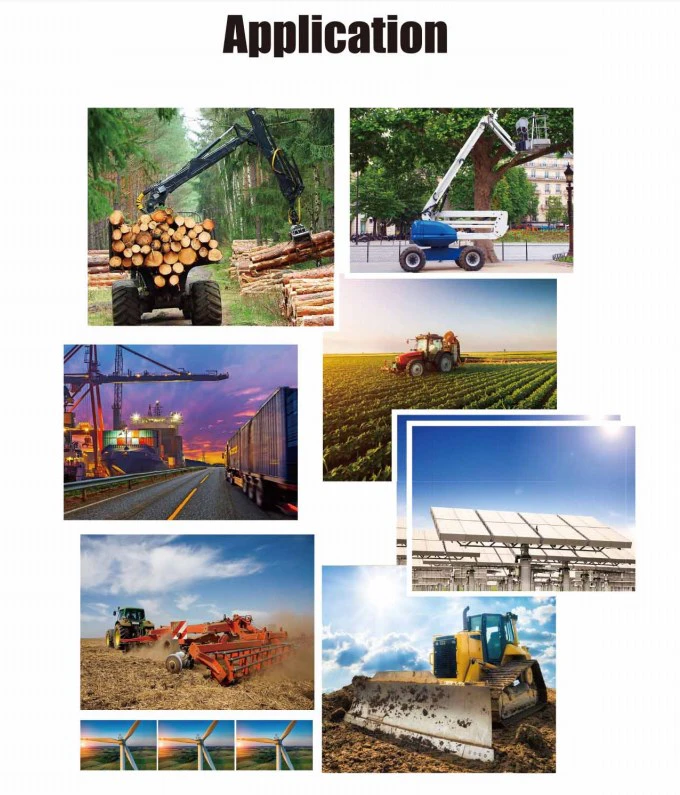

Reach Stacker Luffing Cylinder Application Scenarios:

Reach stacker luffing cylinders are used in a variety of applications, including:

(1) Lifting and moving heavy objects: Reach stacker luffing cylinders are used to lift and move heavy objects, such as shipping containers, machinery, and construction materials.

(2) Positioning and loading objects: Reach stacker luffing cylinders are used to position and load objects onto trucks, trains, and ships.

(3) Unloading objects from trucks, trains, and ships: Reach stacker luffing cylinders are used to unload objects from trucks, trains, and ships.

(4) Stacking objects: Reach stacker luffing cylinders are used to stack objects, such as shipping containers and lumber.

(5) Loading and unloading objects from storage racks: Reach stacker luffing cylinders are used to load and unload objects from storage racks.

(6) Moving objects in confined spaces: Reach stacker luffing cylinders are used to move objects in confined spaces, such as warehouses and factories.

(7) Positioning objects for assembly: Reach stacker luffing cylinders are used to position objects for assembly, such as car bodies and aircraft components.

(8) Lifting and moving people: Reach stacker luffing cylinders can also be used to lift and move people, such as workers who need to access high places.

Reach stacker luffing cylinders are typically used in industrial and commercial settings, but they can also be used in residential settings, such as for lifting and moving heavy objects around a farm or property.

Reach Stacker Luffing Cylinder Maintenance and Care:

Maintaining and caring for a reach stacker's luffing cylinder is crucial to ensure its optimal performance and longevity. The luffing cylinder is responsible for controlling the vertical movement of the boom, and proper maintenance will help prevent malfunctions and extend its lifespan. Here are some guidelines for maintaining and caring for a reach stacker's luffing cylinder:

Regular Inspection: Perform routine inspections of the luffing hydraulic cylinder to check for any signs of damage, leaks, or excessive wear. Look for hydraulic fluid leaks, damaged seals, or dents on the cylinder body. If any issues are identified, they should be addressed promptly.

Lubrication: Proper lubrication is essential for the smooth operation of the luffing cylinder. Follow the manufacturer's recommendations for lubrication intervals and use the appropriate lubricant. Ensure that all lubrication points are properly greased and that no excessive grease buildup occurs.

Cleaning: Keep the luffing cylinder and its components clean to prevent the accumulation of dirt, debris, or corrosive substances. Regularly wipe down the cylinder to remove any contaminants that may cause damage or affect its performance.

Seal Maintenance: Check the seals regularly for signs of wear or damage. Damaged seals can lead to hydraulic fluid leaks and affect the overall performance of the luffing cylinder. If any seals are found to be faulty, they should be replaced promptly by a qualified technician.

Hydraulic System Maintenance: The luffing cylinder is part of the hydraulic system, so it's important to maintain the entire system properly. Regularly check the hydraulic fluid level and condition, and replace or top up the fluid as needed. Follow the manufacturer's recommendations for the type of hydraulic fluid to use and the maintenance intervals for the system.

Operating Conditions: Be mindful of the operating conditions of the reach stacker and the luffing cylinder. Avoid overloading the equipment, as this can put excessive strain on the cylinder and other components. Operate the reach stacker within its designated capacity and adhere to the manufacturer's guidelines for safe operation.

About Our Company

Kingway Hydraulic Machinery Co., Ltd. is a leading company in the hydraulic cylinder market. Our products range from engineering machinery hydraulic cylinders, Agricultural Machinery Hydraulic Cylinders, hydraulic steering cylinders, hydraulic lifting cylinders, and Forklift Hydraulic Cylinders. We have an annual production capacity of 200,000 sets, boasting of 300 sets of various fully automatic CNC production equipment, and fully automatic hydraulic cylinder assembly equipment.

Other Products

We also supply hydraulic cylinders for industrial vehicles, rotary drilling rigs, truck cranes, mining dump trucks, and sanitation machinery. We welcome customers to customize their desired hydraulic cylinders based on their specifications.

Related products

-

Custom Hydraulic Cylinder for Lift Truck/Aerial Work Platform Double Acting Telescopic Hydraulic Cylinders

-

Custom made 500kg hydraulic cylinder for scissor lift OEM Aerial work vehicle hydraulic cylinder

-

Custom Made Hydraulic Cylinder for Industrial Vehicle /Forklift Hydraulic Tilt Cylinder for Loader

-

Custom Made Hydraulic Cylinder for Industrial Vehicle/Forklift Tilt Cylinder